SynRM motor and drive packages: the perfect combination

Bogart and Bacall, Bonnie and Clyde, Laurel and Hardy. Some partnerships seem as if they're just made for each other. In the case of ABB SynRM motors and ABB drives, they actually are.

The classic combination of IE5 synchronous reluctance motors (SynRM) and new ABB drives has been designed to maximise your energy savings. So what does it come with?

- Verified IE5 efficiency (from 1.1 to 350kW, frames 90 to 315))

- Lower bearing and winding temperatures

- Longer bearing life

- Better partial load efficiency

- More precise process control

- Permanent magnet motor performance - without rare earth magnets

Taking you to a new level of ultra-premium efficiency it's a pairing which saves you money and energy, reduces your emissions, improves reliability (and so productivity), enhances sustainability and works in all applications.

See a SynRM case study on a 24/7 operation

Why choose a SynRM motor? When you consider that almost half the electricity in the world is converted to motion by electric motors, it makes sense to make this conversion as efficient and as cost-effective as possible...because if every production line was to be just a tiny bit more efficient...imagine the huge amount of energy worldwide which could be saved? Your SynRM motor has to work in conjunction with a drive - that's one of the reasons it's so efficient, but it takes this partnership with the drive to a new level with the drive switching the frequency of the supply current to the motor thousands of times per second.

Reluctant to make the move to 'reluctance' motors? Cautions about your 'induction' to SynRM? Lots of myths abound about what, in fact, is not new technology. It's well established, and it's been around for almost 100 years.

Let's look at some of the misconceptions about SynRMs, because there are lots:

- It's unreliable because it's new - Ooops, we've already busted that one.

- It's a more complicated motor, so it'll be difficult to repair - Two things here. It's not that different to an induction motor, in fact with no traditional rotor windings you could argue it was simpler to maintain, and secondly, as it runs cooler than a traditional motor, it actually needs less maintenance. It's a very chilled motor...

- It's great, but only for specific applications - As long as your application uses a vsd, a SynRM motor is probably the best (and most energy efficient) choice. Constant torque? It's fine. Quadratic torque? Ditto.

- Well fine, but it's hugely expensive - It's the same price as an IE2 induction motor, but you get the same power from a smaller frame size, or even more power from the same frame...and it's more cost-effective to run. Swapping over the same frame size is ..'simples' as a meerkat might say.

- You can't get drives to match them - All new ABB drives (and even those from other manufacturers) are now compatible with SynRM motors. If you're buying an ABB SynRM package, the drive and motor won't just be compatible, they'll be perfectly matched to give you optimum efficiency.

- So you have to buy them as a package - Nope. You have to have a VSD control this type of motor, but they don't have to be bought as a pair..see above. Any drive supplier worth their salt will be able to show you the energy savings you can make using their drive and a SynRM motor.

- Three words: High torque applications - Well 'extruder' me but three words: Bring it on. It'll perform more quietly, generate less heat and do all of this in a safer fashion than say a PM motor, which can produce high voltages in their terminal boxes if the inverter isn't energising them. Hopefully we 'conveyored' that well enough.

Well, that was quite a list. We were going to provide you with six or so reasons you SHOULD use a SynRM package, but you know what? I think we've covered it.

All you have to do now is email your requirements to motors@edcscotland.co.uk and our motor specialists will take it from there.

See how you can 'put a ring' on one of the best drive and motor partnerships around.

The new IE5 ultra-premium synRM motor

ABB has launched the IE5 SynRM Increased Safety motor, an addition to its award-winning IE5 SynRM series. This new motor offers up to 40% lower energy losses compared to IE3 motors, so it's the perfect choice for replacing standard induction motors in applications such as pumps, fans, and compressors. It has been developed for use in potentially explosive atmospheres across a wide range of demanding variable speed industrial applications.

These SynRM Increased Safety motors not only offer energy savings, they also provide a more cost-effective installation. In Zone 1, the cooler running design could allow the use of an increased safety motor where a flameproof motor and special enclosure would be the established choice. In Zone 2, the improved loadability of SynRM motors is important, enabling more power to be delivered from the same size as an induction motor. This means smaller, lower-cost motors can fulfill the same duty.

This innovation is a world-first and ideal for industries where explosive gas, vapor or dust might be present, such as oil and gas, chemicals, wood processing and flour milling. here SynRM provides accurate control and high efficiency throughout the whole speed range, even at partial loads. And due to their cooler running they require less maintenance, provide better reliability and can be a partner in your process for longer.

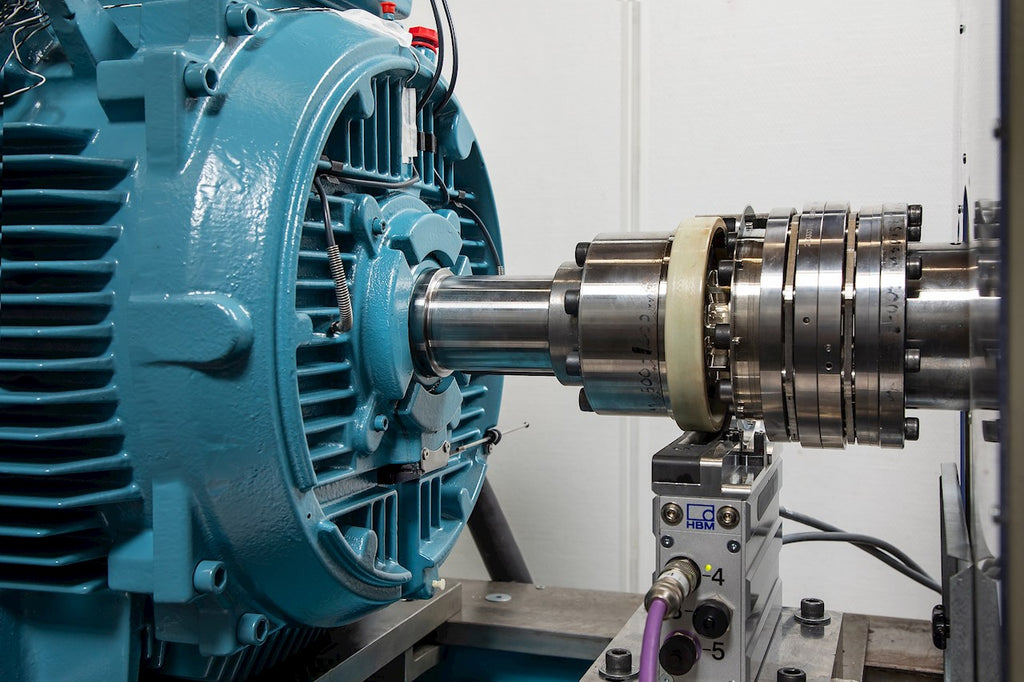

Below is one of the new range of IE5 ultra-premium efficiency SynRM Increased Safety motors on test at an ABB design and development facility. We think it's going to be the best in its class.

Return to ABB motors.