What is a vsd & why use one?

What is a variable speed drive?

Why do we need or use variable speed drives? David Kerr, our Workshop & Commissioning Manager explains:

"To answer this question EDC has outlined some advantages of VSDs below, but before we examine these, let's look at the various ways of controlling rotating machines."

"Firstly, we have what is known as DOL (Direct Online Starters) moving onto star delta starters then auto transformers and lastly, softstarters.

All of these systems use high starting currents, which causes premature wear and tear on couplings and gearboxes, squealing belts and, in some instances, damage to both material and product."

"The above may vary from 3 to 10 times start-up current, depending on the application.

However, with a VSD, we start at zero current and slowly increase to full load or nominal running current of the application. This is done with a 'controlled' and adjustable ramp up and ramp down. By now you can clearly see the benefits - but it doesn't end there. Look more closely and you will see a reduction in energy costs, maintenance and down time. Lastly, the benefit which is often overlooked, is the reduction in carbon into our world - an issue which also reflects on your carbon footprint. I hope I have explained - in brief - the benefits of fitting VSDs to your application. If you would like to take up our offer of free energy surveys, or for a colleague to call you about any aspect of vsd use, please call us. Remember, EDC is here to assist you, not only in your VSD selection, but going forward with you as your company grows."

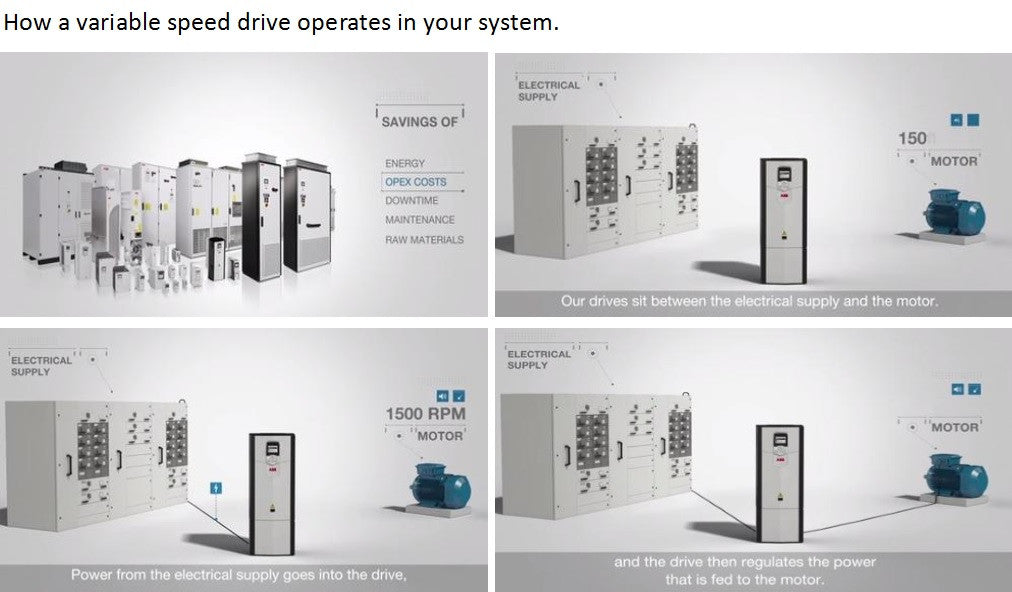

To add to David's explanation, very often, where you have a motor powering equipment, you'll find a variable speed drive. The inverter will be controlling the speed of the motor relative to the demands of the application, seamlessly ramping the motor up and down. The most often used analogy for a variable speed drive is that of a car. The VSD controls the motor just as the gears control a car. Operating motors without controlled starting would be the equivalent of trying to start you car in top gear, and instead of gently slowing down on approach to a red light, speeding up to it, only to brake sharply in the final few meters: you burn more fuel, the vehicle is subject to severe stress and the ride is bumpy and uneven.

This, in essence is the beauty of variable speed drives: seamless and variable control of the application they are running (from as small as 0.18kW up to 5.6 Megawatts). The savings it makes to your company's energy use can also be dramatic, with variable speed drives having the ability to reduce consumption by as much as 60% - and for a 90kW motor in continuous duty, this equates to over £9,000 per year. Smaller applications also benefit, as ABB advises:"A centrifugal pump or fan running at half speed consumes only one-eighth of the energy compared to one running at full speed. This is because the torque needed to run a pump or fan is the square of the volume." To find out how this impacts on the cost of your energy have a look at ABB's Energy Saving Calculator

But apart from controlling the speed & torque of a standard induction (permanent magnet, asynchronous & synchronous) motors, ABB variable speed drives also offers industry the opportunity to:

- Lower maintenance costs, whilst decreasing downtime

- Reduce scrap /ambient noise emissions

- Meet environmental goals & reduce your carbon footprint

- Reduce energy costs

- Fine tune applications

- Lessen harmonics

- Extend machinery life

- Stabilise current demand

- Have lower power demand on start-up

- Adjust torque limits (so your motor never overloads)

- Eliminate gearboxes and other mechanical components (reducing maintenance costs and space requirements)

.